Dino Vinti

Mechanical Engineering and Industrial Automation

About

Projects

Heated Press for LED bonding process

Used for bonding micro LEDs to a flexible substrate. Press platens are able to open and close while maintaining parallelism within 0.05 mm. The inside face of the platens is heated while the outside is chilled to eliminate thermal deformation. A tray system is used to avoid operator hand being placed between the platens. The press is powered by a Danaher electric cylinder, Baldor motor and drive and Galil motion controller. The program is done in Labview.

Deployment Fixture for multibeam sonar

Allows installing a multibeam sonar on different survey boats. The assembly allows the sonar to be oriented in different ways depending of scope of survey while maintaining rigidity of sonar - fixture - boat system. A breakaway device is included to prevent damage to the sonar head in case of an underwater collision. All materials are selected to withstand ocean water.

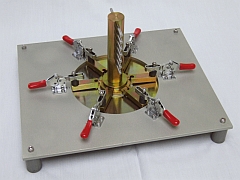

Assembly Jig for heat sink manufacturing

Includes features to allow precise positioning of about fifteen components in three stages while being bonded. Adjustment capabilities are provided while allowing for an unobstructed path for bonding agent dispensing.

Automated Trimming Attachment for sidewall shingles

Allows trimming of non-parallel edges of cedar shingles at a rate of 40+ pieces per minute. Fits onto existing cedar remanufacturing machines while increasing production by 50% and recovering more useful cedar shingle surface. The vision system and motion system are synchronized with the manufacturing line. The vision is based on Baumer sensors while the motion is done with Galil controllers and servo drives.

Copper - Aluminum Cooling Plate for laser head

Performs as good as a full copper watercooled heatsink while reducing weight and cost. All water cooling passages are made out of copper while air cooling fins are made out of aluminum. The copper components are bonded to the aluminum using a special solder and process. A flow control device is included to insure constant cooling capacity.

D. Vinti